VISION

WellToDo specializes in treating nitrate-contaminated while leaving behind clean water and nothing more.

Nitrate is the most common water pollutant in the world. 10% of the global ground water is contaminated with Nitrate at levels that pose a serious health risk. According to EPA data, in the USA alone Nitrate at levels above the maximum allowed limit have been found in water systems serving more than 16,000,000 people.

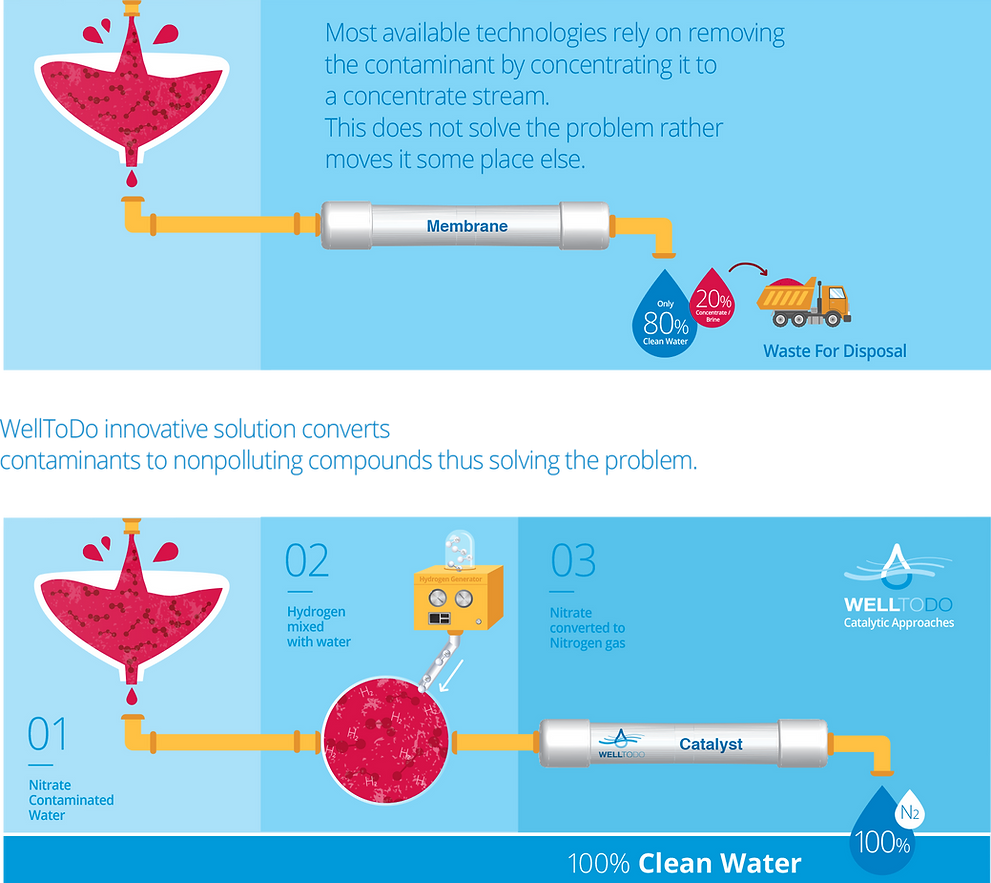

The WellToDo process which converts Nitrate and other common water contaminants into nonpolluting compounds offer significant advantages over existing technologies and enables treating water sources where available technologies are not feasible.

Extent of contamination:

-

Dangerous levels of nitrate are found in 10% of groundwater aquifers globally

-

The EPA estimates that 16 million Americans are exposed to nitrate poisoning

-

Nitrate exposure is known to cause: cancer, birth defects and miscarriages

WHAT IS THE WellToDo PROCESS?

WellToDo developed a unique process to convert various common water contaminants into nonpolluting compounds.

The process utilizes a novel catalyst developed by WellToDo that enables a chemical reaction used to remove the contaminants. The main benefit of this method is that it removes water contaminants without generating any brine or byproducts.

Available contaminants removal methods rely on moving the contaminants from the main water stream and concentrating them into a concentrate stream. This concentrated stream requires further treatment and adds costs and complexity. The WellToDo process is applicable for a wide range of contaminants and in the case of nitrate, it is the only physical chemical removal process that does not generate any concentrate or byproducts.

The WellToDo innovation is twofold. In the world of water treatment, catalysis is a big innovation as these kinds of processes are quite rare. In the world of catalysis, a significant showing by WellToDo is the catalyst support used. Catalysts are metal particles supported on some form of high surface area substrate. Activated carbon is a very common form of catalyst support and is widely used. Activated carbon comes in two main forms:

-

Powdered activated carbon

-

Granular activated carbon

Powdered activated carbon allows for high surface area but, when used as a catalyst support in packed beds, creates a very high-pressure drop through the bed, thereby increasing operational costs. Granular activated carbon offers a low-pressure drop but it's low surface area increases the required reactor volume and system footprint thereby increasing capital costs.

The WellToDo innovative catalyst uses Activated Carbon Cloth (ACC) as the catalyst support. This cloth is woven from micron size fibers of 100% Activated Carbon. The fiber size with its porus surface and the fact that these fibers are woven into a fabric structure, offers an exceptionally high surface area combined with low pressure drop. The benefits gained are:

-

Small reactor volumes

-

Small system foot print and

-

Low pumping costs due to the low pressure drop of the catalyst

This technology is encapsulated in the Catalytic Module – the WellToDo CORE product. This catalytic module is a standard water treatment element ready to be used with off the shelf components to assemble an entire water treatment system.